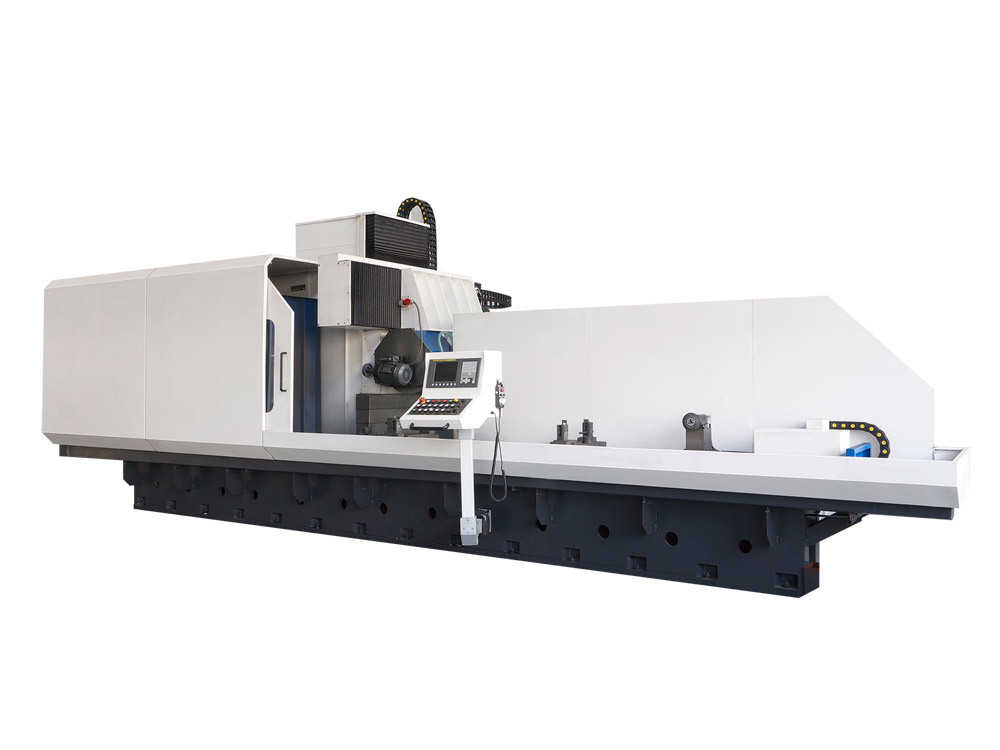

CNC Forming Grinder / CNC Surface Grinder

key word:

CNC Forming Grinder / CNC Surface Grinder

Category:

Description

|

project |

unit |

Specifications |

|

|

Machine specifications |

|||

|

working desk size |

mm |

3000×500 |

|

|

Workbench maximum load |

kg |

1500 |

|

|

Distance from the centerline of the spindle to the table |

mm |

250~750 |

|

|

Worktable longitudinal movement (X axis) |

|||

|

Moving speed |

m/min |

0~30 |

|

|

Maximum stroke |

mm |

3200 |

|

|

Minimum feed |

mm |

0.01 |

|

|

positioning accuracy |

mm |

0.01/300 |

|

|

Grinding head vertical movement (Y axis) |

|||

|

Moving speed |

mm/min |

0~500 |

|

|

Minimum feed |

mm |

0.001 |

|

|

positioning accuracy |

mm |

0.005/300 |

|

|

Grinding head lateral movement (Z axis) |

|||

|

Maximum stroke |

mm |

650 |

|

|

Continuous feed rate |

mm/min |

0~1000 |

|

|

Minimum feed |

mm |

0.001 |

|

|

positioning accuracy |

mm |

0.005/300 |

|

|

Spindle, grinding wheel |

|||

|

Spindle motor power |

kW |

37 |

|

|

Spindle rated speed |

r/min |

1500 |

|

|

Spindle runout |

Axial |

mm |

0.002 |

|

|

Radial |

mm |

0.002 |

|

Grinding wheel size (outer diameter × inner diameter × thickness) |

mm |

560×240×100 |

|

|

Cooling device |

|||

|

Coolant flow |

l/min |

200 |

|

|

Head |

m |

20 |

|

|

Machine size and weight |

|||

|

Dimensions (length × width × height) |

mm |

7000×2500×2700 |

|

|

Machine weight |

kg |

15000 |

|

1

PRODUCT

Get product quotation for free

We will contact you within one working day. Please pay attention to your email.